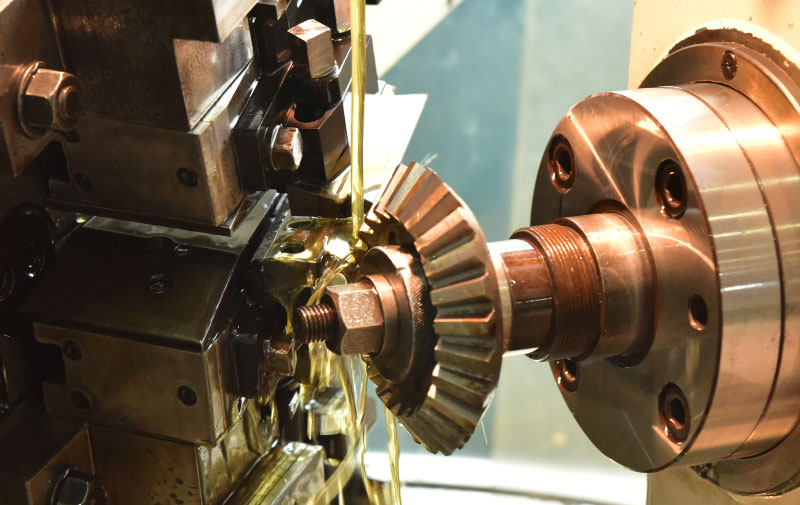

We assist industries with integral maintenance solutions based on Reliability

Industry 4.0

We anticipate problems, design plans that include recommended actions, implement strategies and provide an analysis with a focus on continuous improvement

Join us and transform your industry

We work together with our clients That is the key to continuous improvement

¿What do we do?

Our main differentiating attribute is the application of the world’s latest technologies in an integral way. This, along with the experience and well-recognized career of the professionals that are part of the company

24/7

Readily available for our clients

+50

Experts working along with our clients

90

Current clients trusting our services

100%

Traceability of each method applied

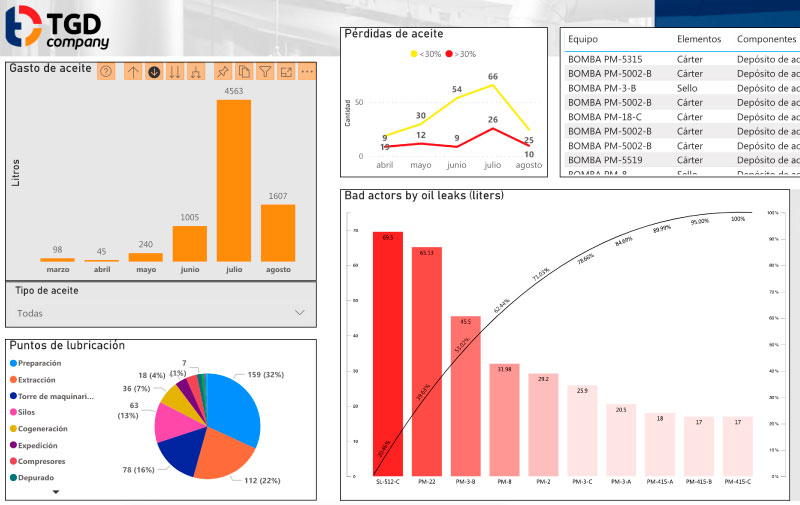

+20.000

Monthly data collected on site by our system

22.000

Assets inspected at present

Our Clients

Contact

+54 9 351 2420072

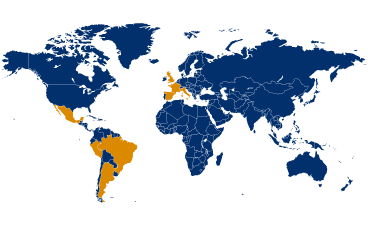

Argentina, Peru, Brazil, Mexico, Spain, France, Italy and United Kingdom